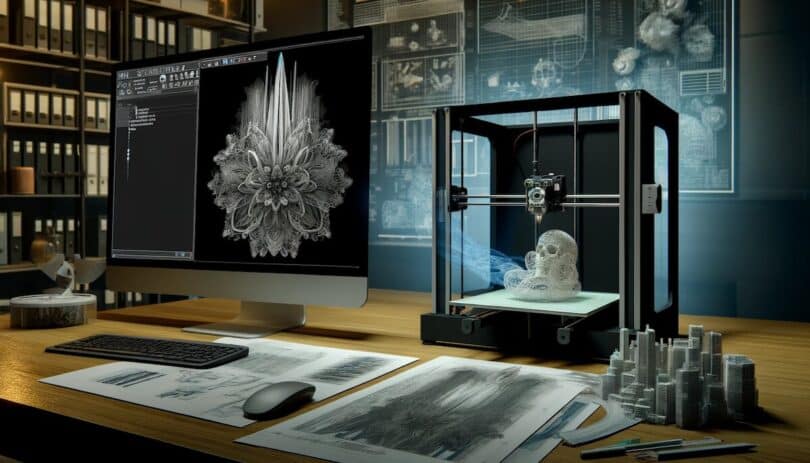

Yes, AutoCAD is well-equipped for 3D printing tasks. AutoCAD, developed by Autodesk, stands as a cornerstone in CAD (Computer-Aided Design) software, widely recognized for its precision and versatility. This software is extensively leveraged across various industries, encompassing architecture, engineering, and construction, to create accurate 2D and 3D models. Its powerful drafting tools and advanced features enable professionals to execute intricate design and complex engineering projects with remarkable efficiency.

Key aspects of AutoCAD include:

- Precision Drafting and Design: AutoCAD’s toolset is designed for producing precise technical drawings and complex geometrical constructs.

- Customizable User Interface: Tailored to enhance productivity, its interface can be customized to suit individual project needs.

- 3D Modeling Capabilities: Beyond 2D drafting, AutoCAD excels in creating 3D models, crucial for visualization and simulation.

- Extensive Library of Pre-Defined Objects: Offers a vast array of pre-defined objects and blocks, facilitating quicker design processes.

- Compatibility and Integration: Known for its seamless integration with other Autodesk products and compatibility with various file formats.

Basics of 3D Printing

3D printing, also referred to as additive manufacturing, marks a significant shift in the way objects are fabricated. This technology operates on the principle of creating physical objects from digital models, employing a layer-by-layer material deposition method. Its transformative impact is evident in fields ranging from prototyping to full-scale manufacturing across diverse industries.

Essential concepts of 3D printing include:

- Layered Fabrication: Objects are built up sequentially, one layer at a time, from various materials like plastics, metals, or resins.

- Digital Model as a Blueprint: Utilizes CAD models as blueprints, translating digital designs into physical objects.

- Versatility in Applications: From custom parts in aerospace to personalized medical implants, the applications are broad and varied.

- Rapid Prototyping: Enables rapid development and iteration of designs, significantly reducing the time and cost of product development.

- Increasing Accessibility: With advancements in technology, 3D printers are becoming more accessible, offering potential for widespread use in manufacturing and even in consumer settings.

Can AutoCAD Create 3D Models?

Absolutely, AutoCAD is more than proficient in the realm of 3D modeling. This powerful CAD software comes equipped with a suite of advanced 3D modeling tools and features, enabling users to construct detailed, complex geometries that are essential in various fields like manufacturing, architectural design, and engineering.

Key aspects of AutoCAD’s 3D modeling capabilities include:

- Versatile Modeling Options: With AutoCAD, you have the capability to craft solid models, intricate surfaces, and detailed meshes. This flexibility allows designers to explore a broad spectrum of 3D shapes and structures.

- Advanced 3D Navigation and Visualization: The software is equipped with sophisticated 3D navigation and visualization tools. These features greatly assist designers in examining and modifying complex models from multiple angles and perspectives.

- Implementing Parametric Constraints: AutoCAD supports the integration of parametric constraints in 3D models. This ensures that the design’s intent and specified dimensions are consistently maintained throughout the design process.

- Material Application and Rendering: The software provides options to assign various materials and textures to 3D models. Coupled with its rendering capabilities, it enables designers to present models in a realistic fashion, a critical aspect for client presentations and design reviews.

- 2D Plan Generation: A significant function of AutoCAD is its ability to generate accurate 2D plans, elevations, and sections directly from 3D models, which is essential during the documentation stages of design projects.

Can AutoCAD 3D Print?

While AutoCAD isn’t equipped to directly control 3D printers, its significance in the 3D printing process cannot be overstated. The software’s primary utility is in the creation and preparation of designs which are then utilized in 3D printing.

It is here that the initial design takes shape and detailed model refinement is conducted. This stage is foundational, setting the stage for the entire 3D printing process that follows.

Converting AutoCAD Models to 3D Printable Formats

A critical step in the 3D printing process is converting models into a printable format. The STL (Stereolithography) file format is commonly used in 3D printing, and AutoCAD is adept at efficiently converting its models into STL files. This conversion is essential for bridging the gap between digital design and physical printing.

AutoCAD’s Capabilities and Limitations in 3D Printing

AutoCAD is renowned for its model creation capabilities, offering precision and versatility in designing complex geometries. However, it’s important to recognize its limitations in the context of 3D printing. AutoCAD lacks native functionality for simulating or executing the 3D printing process. While it can design and prepare models for printing, the actual printing and simulation of how a model will be printed are beyond its scope. This necessitates the use of specialized 3D printing software to handle the actual printing process.

Best CAD Software for 3D Printing

When it comes to 3D printing, a variety of CAD software options are available, each with its unique features and strengths. Notable among them are SolidWorks, Fusion 360, and Rhino.

- SolidWorks: Known for its robust parametric modeling capabilities, SolidWorks is particularly favored in mechanical design and engineering. It offers advanced features for assembly modeling and sheet metal design.

- Fusion 360: This software is unique in its cloud-based approach, offering a comprehensive set of tools for CAD, CAM, and CAE. Fusion 360 is particularly adept at handling complex, multi-disciplinary projects.

- Rhino: Rhino excels in freeform surface modeling, making it a go-to for complex geometries and organic shapes. It’s widely used in architecture, industrial design, and jewelry design.

Comparing AutoCAD with Other 3D Printing-Friendly CAD Software

When juxtaposed with other CAD applications, AutoCAD is particularly noted for its precision drafting capabilities. However, certain alternatives might edge it out in specific areas:

- Organic Modeling: Software like Rhino offers superior tools for creating complex, organic shapes, which can be beneficial in artistic and architectural applications.

- Direct Printer Integration: Fusion 360 and other newer CAD platforms may provide more seamless integration with 3D printing technology, streamlining the workflow from design to print.

Advantages of AutoCAD for 3D Printing

Despite the competition, AutoCAD’s strengths make it a preferred choice for many professionals, particularly for complex design tasks:

- Precision and Detailing: AutoCAD’s precision in drafting and detailing remains unparalleled, crucial for technical and engineering designs.

- Versatility: Its wide array of tools and features make it suitable for a variety of applications, from mechanical parts to architectural plans.

- Industry Acceptance: AutoCAD’s long-standing presence and widespread use in the industry ensure a broad base of support and a vast array of resources for users.

AutoCAD Export STL

What Is An STL File?

An STL file, short for Stereolithography, is a widely used file format in 3D printing and computer-aided design (CAD). It represents the surface geometry of a three-dimensional object without any color, texture, or other attributes often found in more complex file types. The STL format describes the raw, untextured surface of a model using triangular facets, each defined by three points in space and a normal vector that indicates the direction of the outside face of the triangle.

This simplicity allows STL files to be easily generated and interpreted by a wide array of 3D printers and software, making them a standard in the industry for quickly and effectively translating CAD models into physical objects through 3D printing.

Converting Models for 3D Printing

Converting models to STL in AutoCAD is straightforward, involving a few simple commands and ensuring the model is watertight.

Step-by-Step Guide to Exporting STL Files from AutoCAD

- Prepare your 3D model in AutoCAD.

- Use the ‘EXPORT’ command.

- Select ‘STL’ as the file format.

- Define export options and save.

Optimizing STL Files for 3D Printing

After exporting, STL files might need optimization, such as reducing the polygon count for smoother 3D printing.

Importing STL Files into AutoCAD

AutoCAD also allows for the import of STL files, enabling users to edit or analyze pre-existing 3D models.

Procedures for Importing STL Files

- Use the ‘IMPORT’ command in AutoCAD.

- Select the STL file to be imported.

- Adjust the import settings as necessary.

Editing and Refining Imported STL Models in AutoCAD

Once imported, STL models can be edited using AutoCAD’s array of tools, though complex geometries might be challenging to modify.

Practical Applications and Case Studies

AutoCAD is used in diverse fields, from architectural design to engineering, where its precision in 3D modeling greatly benefits 3D printing applications.

Real-World Examples of 3D Printing Using AutoCAD

Notable examples include architectural models, industrial parts, and complex mechanical components designed in AutoCAD and 3D printed.

Innovative Projects and Achievements

Innovations include large-scale 3D printing in construction and customized parts in aerospace, all designed using AutoCAD.

Conclusion and Future of AutoCAD in 3D Printing

Summarizing AutoCAD’s Utility in 3D Printing

In conclusion, AutoCAD stands as a fundamental tool in the 3D printing workflow. Its hallmark lies in its unmatched precision and adaptability, crucial for creating complex and detailed models. AutoCAD’s robust toolset for 3D modeling and drafting makes it an indispensable asset in the transition from digital design to physical realization through 3D printing.

Future Trends and Developments in CAD and 3D Printing Technology

Looking towards the future, the trajectory for CAD software, particularly AutoCAD, and 3D printing technology seems geared towards even more seamless integration. This evolution is likely to include the incorporation of AI (Artificial Intelligence) to enhance design efficiency and accuracy. Furthermore, advancements in advanced simulation capabilities will potentially allow designers and engineers to anticipate and solve real-world challenges within the CAD environment, significantly refining the 3D printing process. These developments promise not only to streamline the workflow but also to open new horizons in customization and complexity in 3D printing projects.