Creating a Bill of Materials (BOM) in AutoCAD is essential for accurate parts lists and efficient manufacturing processes. This guide will show you how to generate, customize, and manage BOMs, including the crucial bom AutoCAD, ensuring your designs are complete and error-free. Learn the techniques and tools you need to streamline your BOM creation process.

Key Takeaways

- A Bill of Materials (BOM) is essential in AutoCAD for listing all parts required for production, facilitating efficient manufacturing processes.

- AutoCAD provides multiple methods for creating BOMs, including attribute extraction and data extraction, which enhance efficiency and accuracy in data gathering.

- Integration with tools like OpenBOM enables seamless collaboration and automation in BOM management, ensuring up-to-date information across procurement and manufacturing teams.

Understanding BOMs in AutoCAD

BOMs guide the manufacturing process by:

- Listing all parts needed for production.

- Helping identify affected components during engineering changes, making cost calculations more efficient.

- Simplifying or standardizing products by highlighting unique components that increase maintenance costs and suggesting standard alternatives.

Recent Autodesk developments now allow BOM generation directly from CAD files using Fusion.

AutoCAD offers methods like attribute extraction and data extraction to generate detailed parts lists, which are vital toolsets for an inventor in manufacturing, including support for dwg files.

Creating BOMs in AutoCAD is a strategic task that can significantly enhance the efficiency and accuracy of manufacturing processes.

What is a Bill of Materials?

A Bill of Materials (BOM) is a parts list used to guide the manufacturing process, detailing what is needed to produce a product. It includes vital details such as:

- Part names

- Quantities

- Descriptions

- Materials used

In AutoCAD, a Bill of Materials (BOM) is required. You need it in order to utilize parts lists and balloons. This means that creating a BOM is the first step in ensuring accurate parts lists and balloons in your design.

When you create a BOM in AutoCAD, it includes all the parts, part references, parts, and assemblies. This comprehensive approach ensures that every component is accounted for, enabling a seamless integration of design and manufacturing processes.

AutoCAD LT cannot create a bill of materials automatically from CAD files, making the full version of AutoCAD essential for this task.

Types of BOMs in AutoCAD

There are three main types of bills of materials in AutoCAD:

- Hierarchical BOMs: Use a tree structure to show parent-child relationships, aiding in visualizing assembly. This structure is particularly useful for complex projects where understanding component relationships is crucial.

- Flat BOMs

- Structured BOMs

On the other hand, flat BOMs present a straightforward list of components without nested levels, making it easier to see quantities and basic information. Tools like OpenBOM can automatically generate both hierarchical and flat BOMs, ensuring flexibility based on project needs. This flexibility lets you choose the BOM structure that best suits your project, whether it’s a detailed hierarchical view or a simple flat list.

Creating BOMs in AutoCAD

Several methods can be used to create BOMs in AutoCAD, each with its own advantages:

- Automation tools in AutoCAD can significantly reduce the time and effort required for BOM creation.

- Users can extract BOMs directly from blocks.

- BOMs can be extracted from attributes.

- BOMs can be extracted from tables.

These methods make the process more efficient and less prone to errors.

One common method for creating BOMs in AutoCAD is the use of attribute extraction (ATTEXT) and data extraction (DATAEXTRACTION). These methods streamline the process of gathering essential data for BOMs. Additionally, tools like OpenBOM provide BOM Integration capabilities for AutoCAD that further enhance the efficiency of BOM creation, linking parts information directly to CAD models.

Using Attribute Extraction (ATTEXT)

The ATTEXT command allows users to export information from block attributes directly into a text file. This process streamlines the gathering of essential data for BOMs by allowing direct extraction from block attributes. The attribute extraction process does not alter the original drawing, ensuring that your design remains intact while you gather the necessary information.

Using the ATTEXT command involves a few simple steps. First, you need to select the block attributes you want to extract. Then, using the ATTEXT command, you can export this information into a text file. This method is particularly useful for projects where block attributes contain all the necessary data for your BOM, making the process quick and efficient.

Using Data Extraction (DATAEXTRACTION)

The DATAEXTRACTION command allows users to gather property data from various object types for BOM purposes. This command retrieves detailed property data from various object types, making it a versatile tool for constructing BOMs. To effectively utilize automatic data capture in AutoCAD, it’s essential to configure the system to gather all pertinent details for the BOM.

Automatic data capture involves defining the properties for your BOM. Once configured, AutoCAD can update the BOM as changes are made to the drawings, ensuring it is always accurate and up-to-date, reducing the risk of errors.

Using OpenBOM for AutoCAD

OpenBOM integration https://www.openbom.com/cad-integrations enables structured BOM creation directly from AutoCAD drawings. With OpenBOM, users can manage BOMs more efficiently by linking parts information directly to their CAD models. This integration ensures that your BOMs are always aligned with your design data, providing a seamless workflow from design to manufacturing.

Users can download OpenBOM’s CAD integrations from the “Integrations” button on the OpenBOM website. These integrations:

- Are available for both desktop and cloud-based CAD systems

- Make it easy to set up and use OpenBOM

- Leverage OpenBOM’s full power in creating and managing BOMs

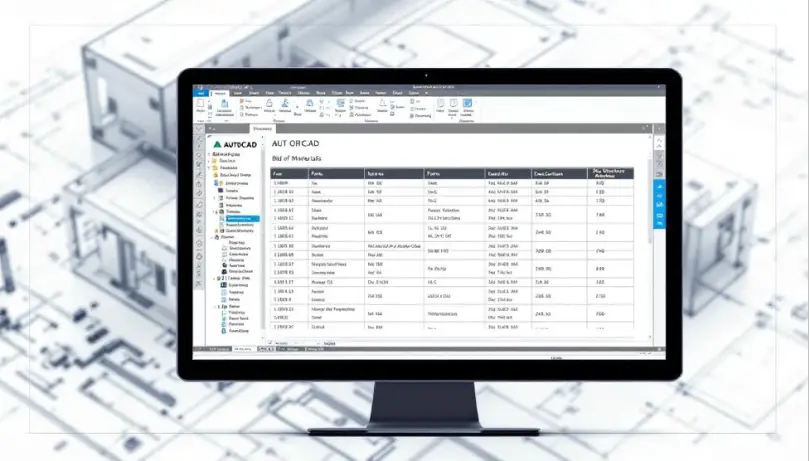

Customizing Your BOM in AutoCAD

Customizing your BOM in AutoCAD ensures it meets your project’s specific needs. The BOM Settings dialog box helps by allowing you to:

- Manage component properties

- Drag-and-drop properties into parts lists and balloons

- Create custom component properties

- Modify predefined properties to fit project needs

Customization options in AutoCAD include:

- Defining new properties

- Synchronizing them with BOM settings

- Adjusting item numbering

- Adjusting font styles

- Adjusting border styles

These options allow you to tailor your BOM to match your project’s requirements, ensuring that all necessary information and quantity are included and displayed in a clear and organized manner.

Mapping AutoCAD Properties to BOM Data

Mapping AutoCAD properties to BOM data involves:

- Creating an attribute extraction template file.

- Defining how the extracted data will be structured in the template file.

- Including at least one field in the template for the data to be collected.

- Mapping AutoCAD properties such as Part Number, Description, and Material to OpenBOM item data.

Mapping properties ensures your BOM includes all relevant information in a structured format, maintaining consistency and accuracy, making it easier to manage and use in downstream processes.

Formatting and Displaying BOM Tables

Formatting and displaying BOM tables in AutoCAD involves customizing columns, headings, and layout. By changing the captions of component properties, you can present the information in a way that best suits your project.

AutoCAD allows users to adjust the layout of BOM table, including column widths and header colors. These customization options ensure your BOM tables are informative, visually appealing, and easy to read, facilitating better communication and understanding among team members.

Exporting BOMs from AutoCAD

Exporting a BOM from AutoCAD allows users to convert their parts lists into formats that can be utilized in various downstream processes. AutoCAD provides several options to export BOMs to various formats suitable for different applications. This capability enhances collaboration and efficiency by providing comprehensive parts lists in formats that are compatible with other software.

Excel spreadsheets in XLSX format, accommodating up to 1 million rows, are a common format for exporting BOMs and CSV. This format is widely used in procurement and manufacturing processes, ensuring easy integration with other systems and tools.

Integrating BOMs with Procurement and Manufacturing

BOMs serve as the primary reference for purchasing materials and components required for manufacturing. They help procurement teams order components for timely delivery, ensuring smooth manufacturing operations. The Manufacturing BOM (MBOM) encompasses all components needed for the production of a final product, facilitating efficient manufacturing processes.

OpenBOM connects design data with procurement, manufacturing, and operations for mechanical structure components, architectural systems, or electrical layouts. This integration ensures all departments have access to the latest information, improving collaboration and reducing errors.

Cloud-Based Collaboration with OpenBOM

OpenBOM allows teams to collaborate in real-time, improving the sharing of product data across different departments. As a SaaS platform, OpenBOM allows CAD files to be easily uploaded to the cloud and enables remote CAD integration setup, regardless of whether the CAD system is cloud-based or desktop-based.

This cloud-based collaboration enables procurement and manufacturing teams to work together more effectively, ensuring that all team members have access to the most up-to-date information from companies. This improves efficiency and reduces the risk of errors in the production process.

Managing Revisions and Catalogs

Maintaining up-to-date BOM records is crucial for confirming warranty status and addressing product changes. A centralized platform like OpenBOM ensures all team members have access to the latest information, enhancing collaboration and reducing errors.

OpenBOM allows users to manage revisions, catalogs, vendors, and more in a centralized platform. This capability helps teams handle various aspects of product management, ensuring that all information is accurate and up-to-date.

Automating BOM Generation in AutoCAD

Automation tools enhance the efficiency of creating BOMs by minimizing manual data entry and reducing errors. These tools allow users to extract data automatically, decreasing the time spent on manual entry and potential inaccuracies. By reducing manual efforts, automation lowers the risk of human error, resulting in more accurate BOMs.

Ultimately, these automations streamline the BOM generation process, facilitating quicker project execution and improved productivity. Automation is an essential tool for enhancing the BOM creation process in AutoCAD.

Leveraging OpenBOM Automations

OpenBOM automations offer the following benefits:

- Streamline the process of capturing product data from CAD, allowing for efficient creation of BOMs without manual intervention.

- Facilitate CAD-neutral geometry generation, enhancing compatibility across different engineering workflows.

- Support downstream processes.

The generation of CAD-neutral geometry is crucial as it enhances compatibility across different engineering workflows and supports downstream processes. Component properties in AutoCAD can be set to sum numeric data within BOMs, enhancing overall data management efficiency.

Setting Up Automatic Data Capture

AutoCAD allows users to define and customize properties for BOMs to include formulas that update automatically as new objects are added. OpenBOM supports automatic item and BOM capturing mechanisms, including files and all related information.

Setting up automatic data capture involves configuring the system to gather all pertinent details for the BOM. Once configured, AutoCAD can automatically update the BOM as changes are made to the drawings, ensuring that your BOM is always accurate and up-to-date.

Summary

Mastering BOMs in AutoCAD can significantly enhance your design and manufacturing processes. By understanding the types of BOMs, creating them efficiently using tools like ATTEXT and DATAEXTRACTION, and leveraging the power of OpenBOM, you can ensure that your BOMs are accurate, up-to-date, and seamlessly integrated with procurement and manufacturing. Customizing BOMs to fit specific project needs and automating their creation further streamline your workflow, reducing errors and improving productivity.

In conclusion, the journey to mastering BOMs in AutoCAD is one of continuous learning and adaptation. By implementing the strategies and tools discussed in this guide, you can transform your approach to BOM creation and management, ensuring that your projects are executed with precision and efficiency. Embrace these techniques, and watch as your design and manufacturing processes become more streamlined and effective.

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a detailed list required for product manufacturing, encompassing part names, quantities, descriptions, and materials. It serves as an essential reference for production planning and inventory management.

How can I create a BOM in AutoCAD?

You can create a Bill of Materials (BOM) in AutoCAD using attribute extraction (ATTEXT) or data extraction (DATAEXTRACTION), and tools like OpenBOM can facilitate structured BOM creation. Consider employing these methods to efficiently manage your components and assemblies.

What are the types of BOMs available in AutoCAD?

AutoCAD offers three main types of BOMs: hierarchical, which illustrate parent-child relationships; flat, which provides a simple list of components; and structured BOMs that categorize components systematically. Each type serves different organizational needs in your design projects.

How can I customize my BOM in AutoCAD?

To customize your BOM in AutoCAD, use the BOM Settings dialog box to manage component properties, create custom properties, and adjust settings for item numbering and font styles. This will enhance the presentation and functionality of your BOM.

What are the benefits of using OpenBOM for BOM management?

Using OpenBOM for BOM management provides the benefit of efficient BOM creation and management by linking parts information directly to CAD models, facilitating real-time collaboration and automatic data capture. This significantly reduces the need for manual tracking and improves compatibility across various workflows.